I agree Our site saves small pieces of text information (cookies) on your device in order to deliver better content and for statistical purposes. You can disable the usage of cookies by changing the settings of your browser. By browsing our website without changing the browser settings you grant us permission to store that information on your device.

At Southern Liquid Systems, we offer high performance cold applied, fast-curing waterproofing and surfacing systems to waterproof balcony floors. Our systems are suitable for high traffic areas.

As many balcony areas are create above living spaces, it is imperative the balcony surface is sealed and waterproofed correctly. Balcony areas account for an extremely large percentage of building defect complaints, making it the highest failure rate of all areas across the building envelope.

Balconies are exposed to the elements, with the requirement of handling frequent rainfall and snow in the winter months. This makes the choice of balcony waterproofing membrane an essential element in any building works. As well as choosing the correct waterproofing membrane it is also vital the installation is completed to a good standard.

Balconies are an important part of any building design. They often offer the only open living space in built up areas. Today, new construction, especially in built up city areas is very focused on high storey construction. Many of these buildings have balconies as part of the construction. Poorly waterproofed balconies often have an impact on residents in the building below and so ensuring a balcony is correctly waterproofed cannot be stressed enough.

A waterproofing membrane is needed for protecting any area underneath the balcony from water ingress. Balconies are exposed to snow and rainfall. This makes it important they are waterproofed correctly. Balconies are often located above living areas and if they fail to keep out water, they have an immediate impact on the affected properties underneath. Internal water damage can prove to be expensive to put right, both in decorating and consequential damage. Waterproofing balconies prolongs the substrate condition, protecting the surface area from gradual degradation due to water ingress taking a toll over the years. Effort is therefore required to sealing a balcony waterproofing membrane correctly and ensure it performs as an integral element of the building structure. Balconies suffer from a high failure rate compared to other areas of the building. However only 1.8% of the construction cost of the building is spent on waterproofing balcony areas. This means nearly 85% of defect complaints involve balconies.

There are several ways to waterproof a balcony. The traditional method involved asphalt. Nowadays hot works are less popular as health and safety issues become more important. Walkways would come under a different process as seamed areas are prone to damage and failure. Seamed systems are not suitable for walkways. But they can be used on balcony areas which do not have to withstand heavy traffic. The reason for this is because they are much less prone to damage from wear and tear. Sealing flat roof balcony areas, balconies on top of occupied space and terrace areas should be approached in the manner befitting an important part of the structure, the consequences can otherwise be severe.

The most popular modern method to coat balconies and walkway areas would be using a liquid coating (often liquid plastics are used). This has many different options contained within it. Hot melt, cold melt, PU liquid and PMMA all are often considered one and the same. Each system has it's own advantages when used as a waterproofing layer.

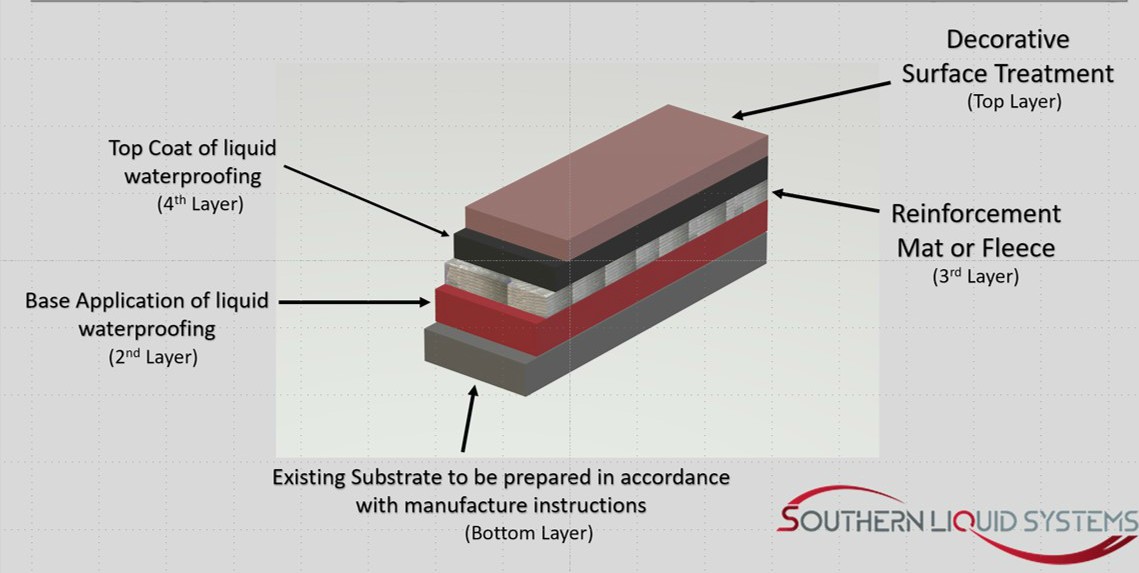

All of these involve coating the substrate with a liquid, be it hot or cold. Preparation may vary slighlty between balcony waterproofing prodcuts. This will be detailed in the technical documentation. You would typically prepare a concrete substrate by ensuring all cracks are filled and loose materials are removed. You would then apply a waterproofing primer to the entire surface. Next, the upstand and detail areas would be coated (Maris Detail is perfect for this element). Then, finally the entire surface would be coated with the chosen liquid waterproofing solution. A second layer is applied to provide a wear coat as opposed to the first coat which is for waterproofing.

Typically, 2kg/m2 of modern liquids is the bare minimum for trafficked areas and an anti-slip product, such as quartz would be broadcast into the topcoat. This can then, if required, be coated with a finishing layer using thin coat or a transparent product (Mariseal Maritrans is ideal for this). The key considerations in a real situation are cure times (busy walkway areas), safety (flame free is preferred), speed of installation, odour in built up areas and obviously overall cost. Products such as Mariseal 250 cure from ground and air moisture. This allows anti-slip aggregates to be applied during the curing of the waterproofing layer, increasing the speed of the installation process.

There are lots of new technologies and materials available in the market. With these new waterproofing systems come improved and more efficient installation methods. Balcony substrates are normally constructed from concrete or timber. This substrate is then protected with a waterproofing membrane. Concrete, timber and metal substrates comes with their own unique considerations. Waterproofing products for one substrate may not be suitable for others. It is important waterproofing systems used can expand correctly with the building. GRP for instance can prove disastrous in some settings as it has barely any expansion properties and often will crack. Obviously any crack in a balcony floor is a clear sign water ingress is a high risk.

It is also important to have a maintenance programme in place. This normally means an inspection every 6 months and can easily be arranged with the original installer. If cared for and maintained correctly the substrate will last as it should. Most repair works which are carried out are more expensive than they need be due to neglect making any simple situation much worse than it needs to be.

A typical build up on a heavy use balcony area using the Mariseal 250 system. A strong, hardwearing topcoat is applied for added durability.

Yes, different substrates require different preparation. Some substrates will always need priming (concrete tiles in hallways), some do not really need a primer, for instance asphalt (although primer is often used to provide a good bond and stop the bitumen bleeding through). Some substrates like worn asphalt may have cracks and bubbles which need taking care of prior to coating. Timber will need the joints taping and reinforced before priming the surface.

Balconies and walkways are external elements of the building and as such are subject to all types of weather conditions. These being sunlight, rain, and very low temperatures. Other factors such as foot traffic, organic growth and the corrosive effects of pedestrian transferred chemicals (including rock salt) must be considered. This shows what waterproofing systems for balconies must withstand.

Liquid waterproofing systems are suitable for the protection of the substrate of any balcony or walkway if it can meet the following conditions:

• Allow for a finish layer which allows for an anti-slip waterproofing system.

• Have a waterproofing membrane capable of withstanding the demands of the balcony or walkway's intended use (for example an area which will endure heavy use will have the ability to have a finish with extra hardness similar to the type used on parking decks).

Liquid systems can be used on the most complex of details, which are often found around handrail supports, thresholds, rainwater outlets and down pipes. These hard wearing, textured systems may be fleece or structurally reinforced.

• Fast and easy to apply.

• Minimum of disruption to residents

• Hard wearing

• Fire resistant (for instance Mariseal has Brooft4 fire certification)

• Can be decorative and anti-slip resistant finishes

• UV resistant with good colour stability

• Capable of bridging cracks and joints

• Easy to clean

This all depends on the workmanship, thickness of liquid membrane, intended use (it stands to reason the more wear a system gets put under the shorter the lifespan expectancy) and quality. Taking this into account a balcony should be able to last for at least 10 years and up to 25 years. A maintenance programme is recommended as this can prove to be very cost effective.

The main benefit of using liquid waterproofing is the simplicity of installation by trained personnel. Maintaining a balcony therefore is often straight forward. If cracks appear these can simply be filled and coated over, often with a single coat (Maris Detail Liquid). As in all roofs and waterproofed areas, organic growth should be removed, and care should be taken when placing heavy of sharp objects on the area.

Based on delivery costings, not material costs, a typical installation based on 20 years warranty should be anywhere for £50 to £80 per SQM. It pays to research this element as some systems are easier to install and much more cost effective consequently. PU (balcony waterproofing products like Mariseal 250 provide a good example when used in conjunction with a 400/420 topcoat) is often better priced than PMMA for instance and can provide the same advantages without many of the potential issues during install. Strong odour being a main concern to many residents.

Modern day construction is heading towards a flame free, safety conscious construction wherever possible. Liquid waterproofing offers a hazard free (PUD Technology) option. It is fast, safe, and easy to install, causing minimal disruption to residents where refurbishment programmes are concerned. Mariseal 250/250W is a perfect option in this environment and is a typical option a specifier should consider.

For this reason, the sealing of balcony areas needs to be planned thoroughly by approved liquid roofing contractors to prevent costly problems further down the line. If you have any questions on liquid waterproofing a balcony area or require a quotation on an upcoming project please get in touch or call us on 0207 7818153. One of our expert surveyors will be happy to help you.